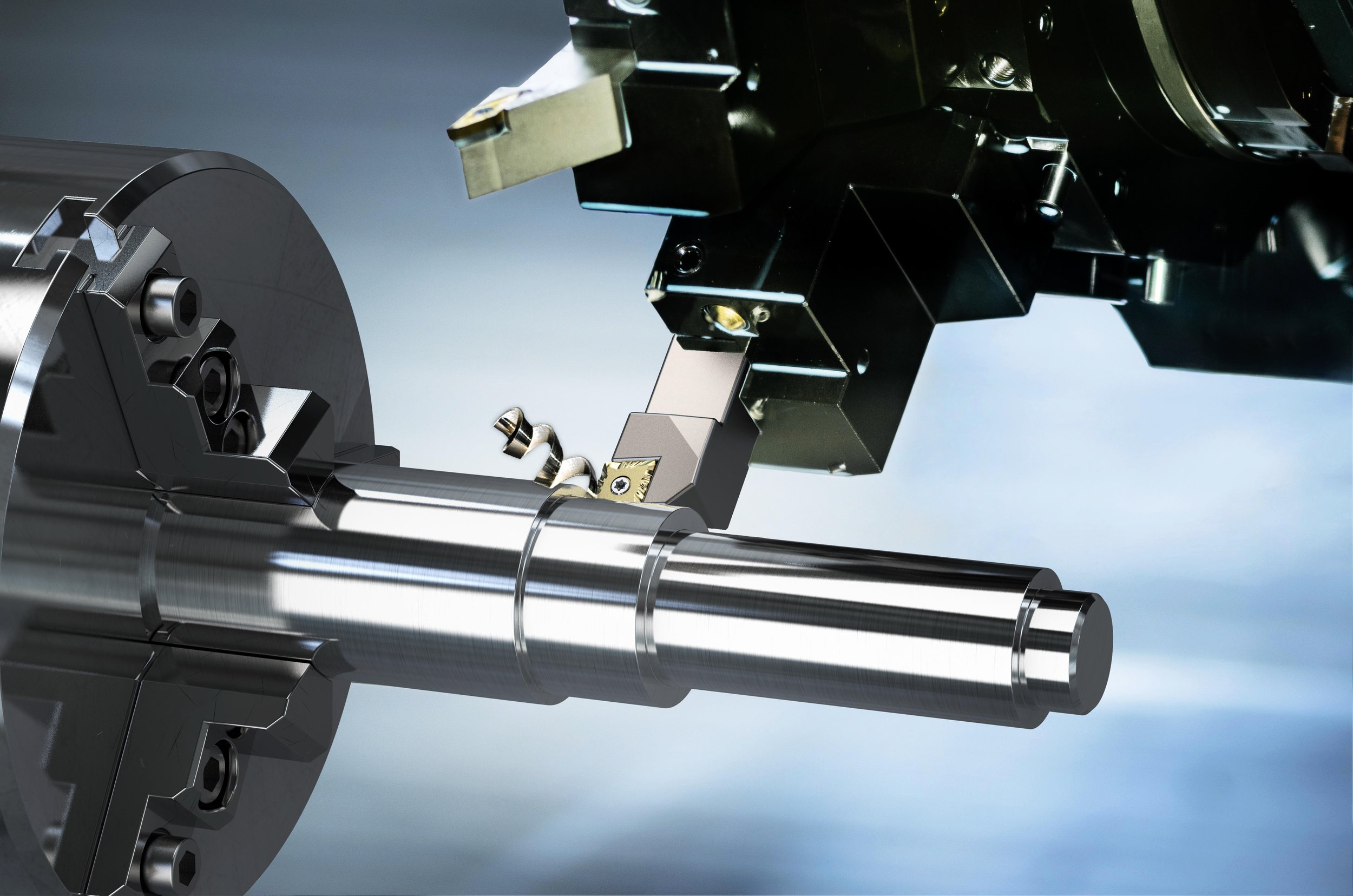

CNC Operator

Programs dedicated to serving Native American Communities through education and opportunity.

-

Paid Education and OJT

CNC Manufacturing-driven education combining 40-hour paid work weeks with on-the-job (OJT) training.

-

Mentorship and Progress Incentives

Students benefit from mentor support and progress incentives to encourage growth.

-

Interactive and Real-World Learning

Hands-on lessons via PC/DVD, state-of-the-art equipment, real-world projects, and customer interaction.

-

Lean Training for Efficiency

Focused training on "lean" principles to enhance educational and operational efficiency.

-

Foundational Maintenance and Operations

Training covers general housekeeping, preventive and tooling maintenance, benchwork de-burring, hand tools, and CNC lathe operations with machine controls.

-

Production, Quality, and Logistics

Students learn blueprint reading, inspection techniques, material handling, inventory control, quality control, and shipping processes.